It means following Industry 4.0 principles. And the last big driver of Industry 4.0 is simply growing adoption. Industry 4.0 is not a new concept, and while there were big early adopters, it’s continuing to gain momentum and be adopted by mid-sized and smaller manufacturers. Industry 4.0 has been here for a while, it’s viable and beneficial.. Management thinker and ‘father of Industry 4.0’ Henrik von Scheel describes three key drivers for Industry 4.0 success: think value, not tech; think people, not tools; and set clear targets from the start. In a large open office in western Australia a team of engineers pore over the 3D image of a nickel and cobalt mine on a screen.

10 Perchè un Azienda Deve Investire in Industria 4.0?

The power of Industry 4.0 Simulation RESTART

Benefits of Industry 4.0 SL Controls

Pharma Manufacturing Digitalization and Industry 4.0 Oxford Global

INDUSTRY 4.0 The Digital Technology Transformation by WINIX Technologies Medium

Industrial digital transformation ICT Group

Industry 4.0 Impacts Manufacturing RTM World

Adapt or die Why Europe’s business must embrace Industry 4.0 Digital Transformation Hub

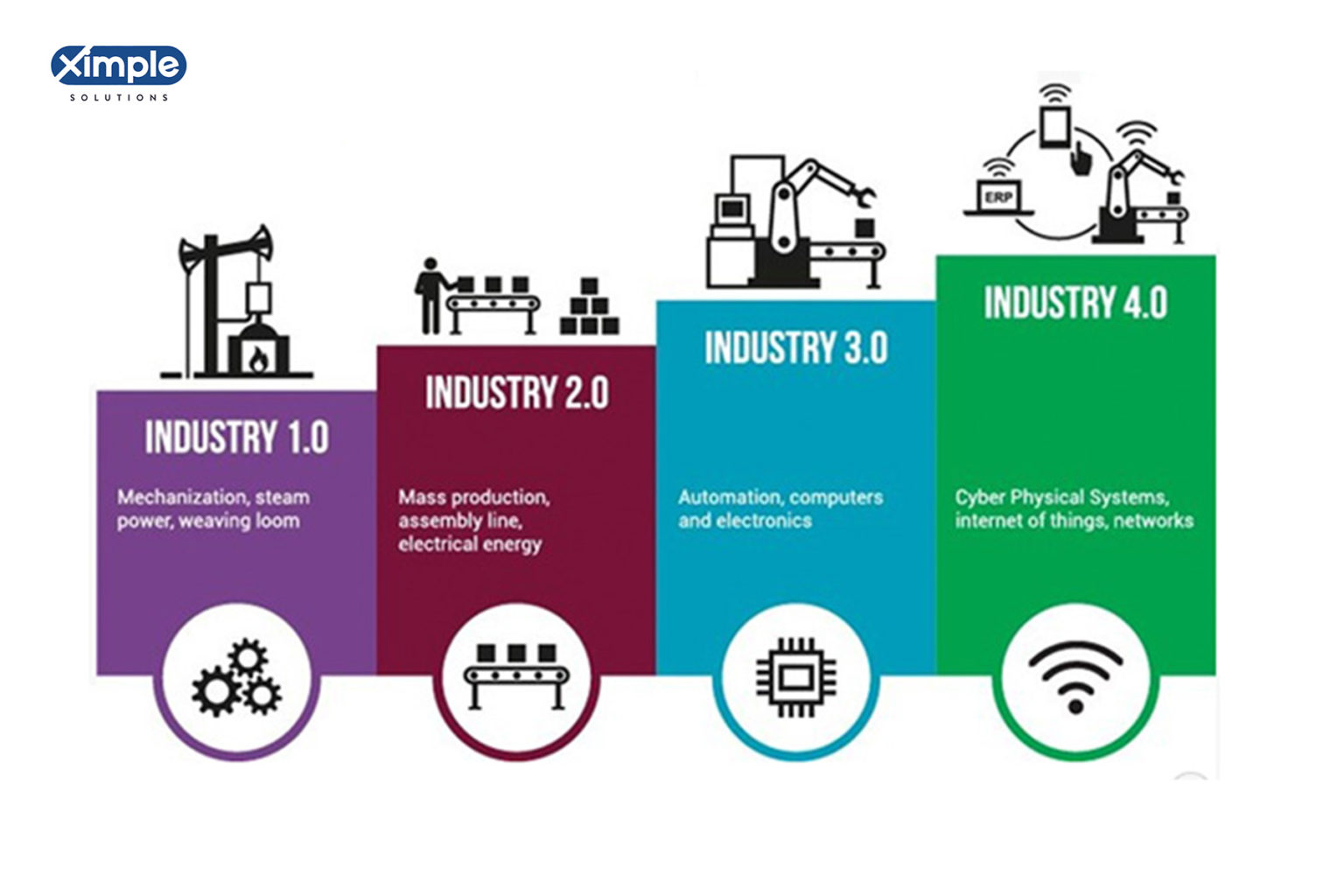

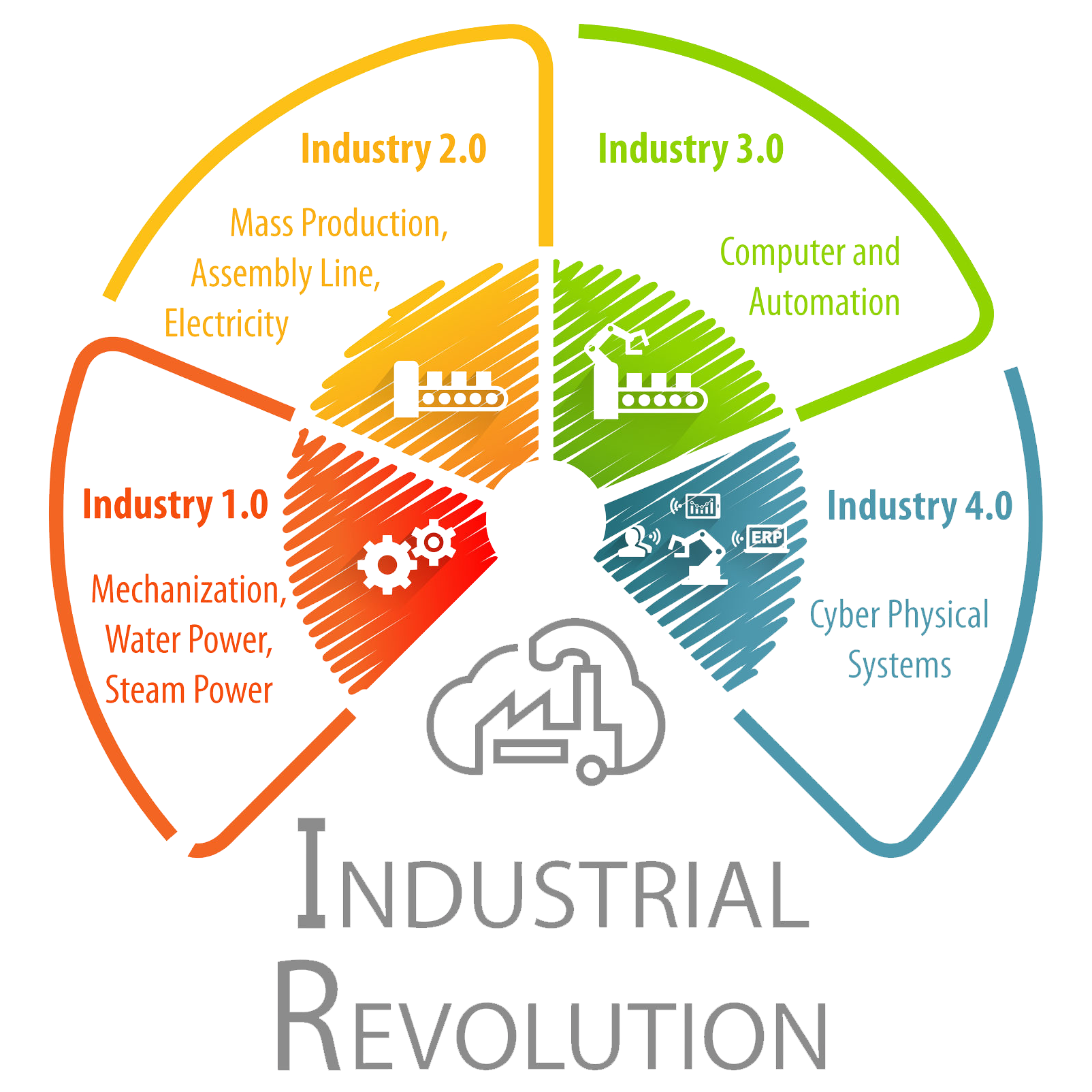

Industry 4.0

Planning for Industry 4.0 with Simulation SIMUL8

Industry 4.0 Challenges and Solutions for the DigitalTransformation and Integration of

Industry 4.0 Technologies to Kickstart Your Digital Transformation

Industry 4.0

Series 3 Manufacturing Equipment & Automation Article 7 Beyond Industry 4.0 …….. Industry 5.0?

INDUSTRY 4.0 CLOUD ERP Your Way To Success

Components of Industry 4.0 stock illustration. Illustration of diagram 172684021

Smart industry/ Industry 4.0

Industry 4.0 value drivers and levers [19] Download Scientific Diagram

Industry 4.0 Infographic Redimark

Framework for the implementation of Industry 4.0 in supply chains Download Scientific Diagram

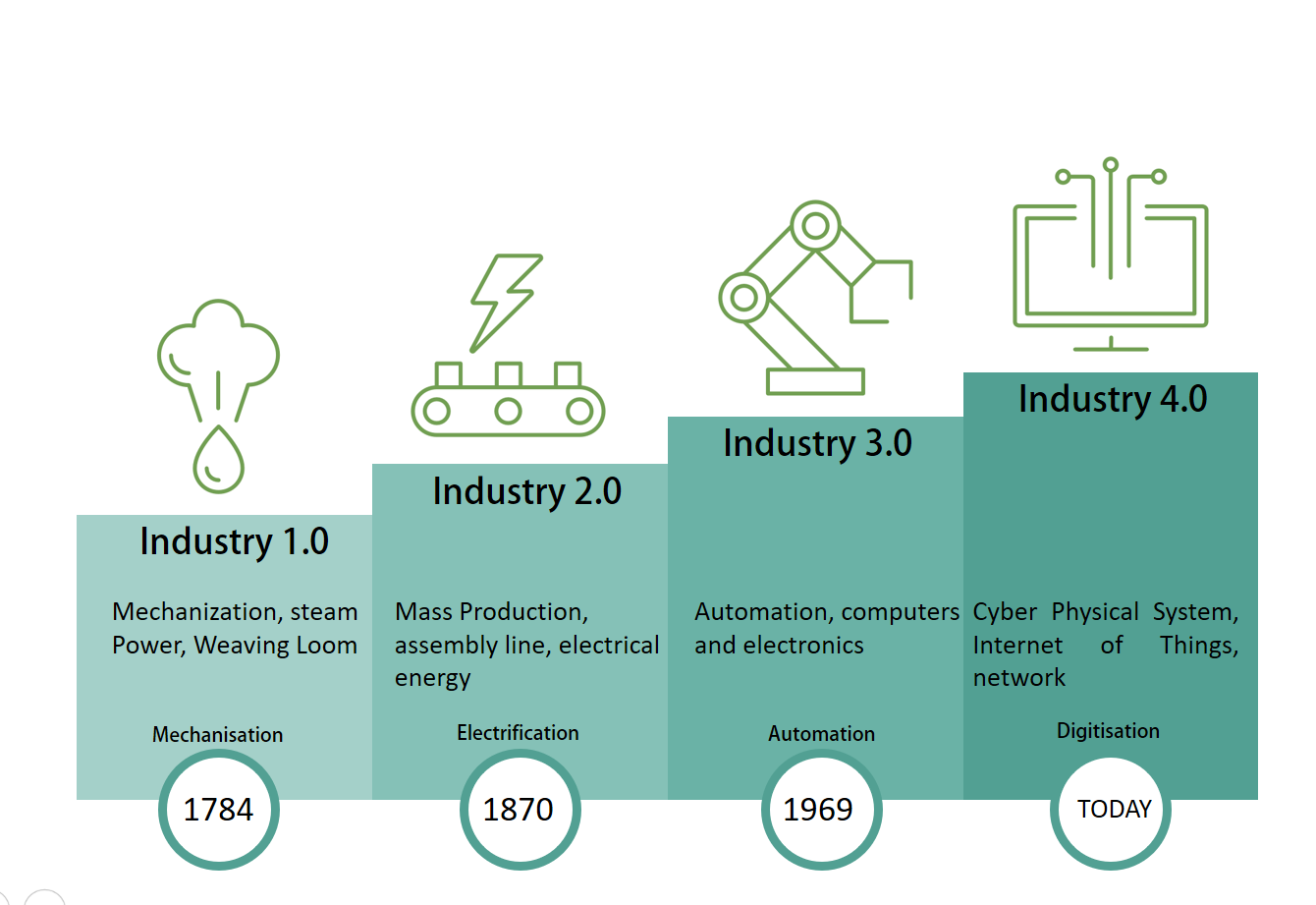

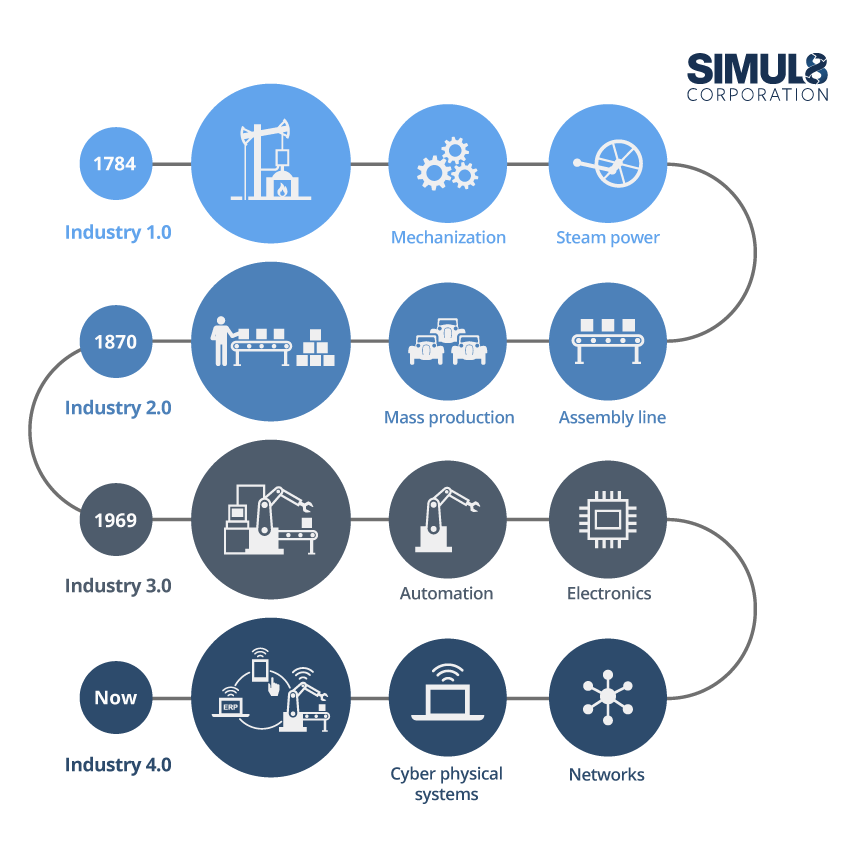

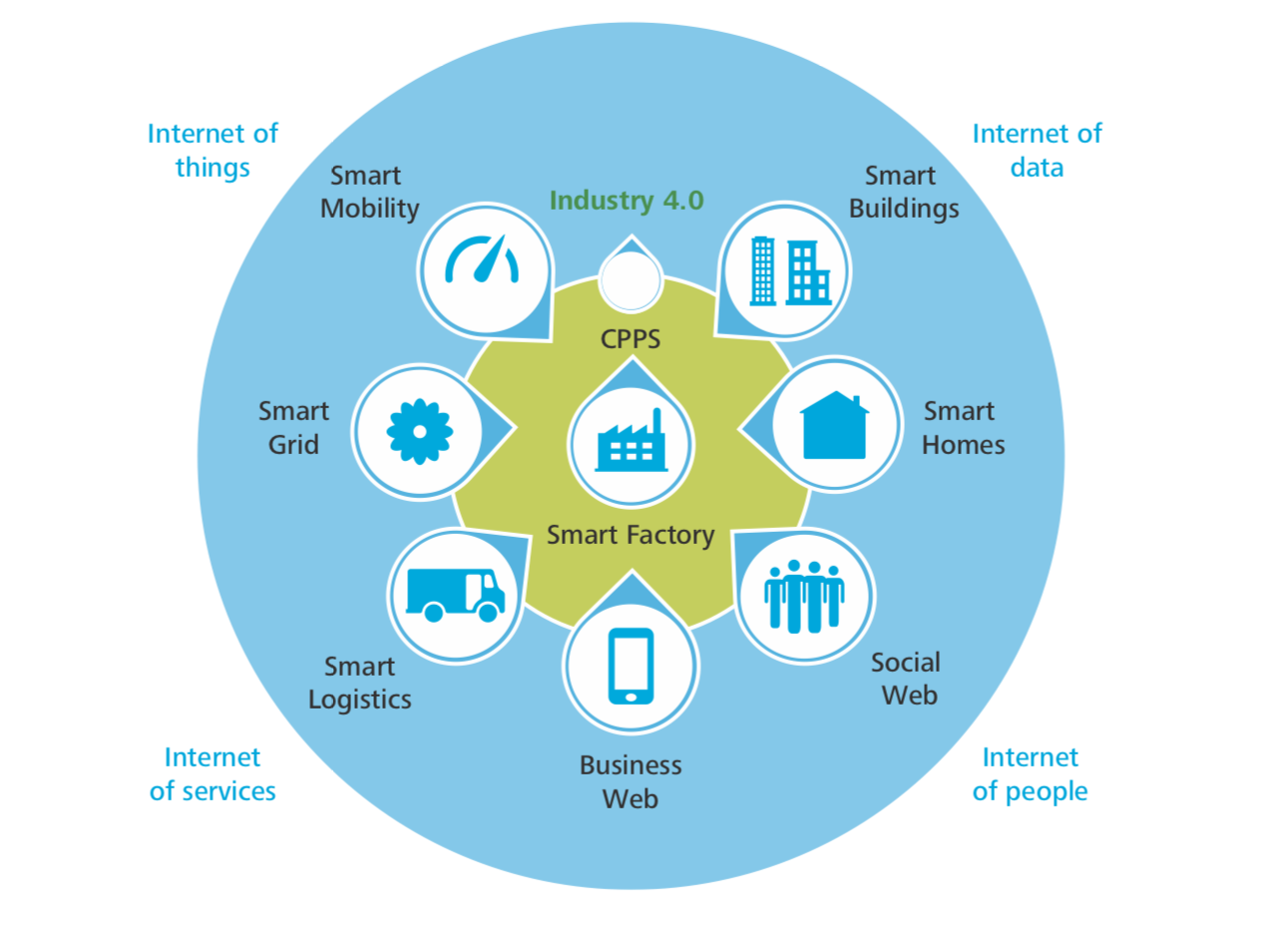

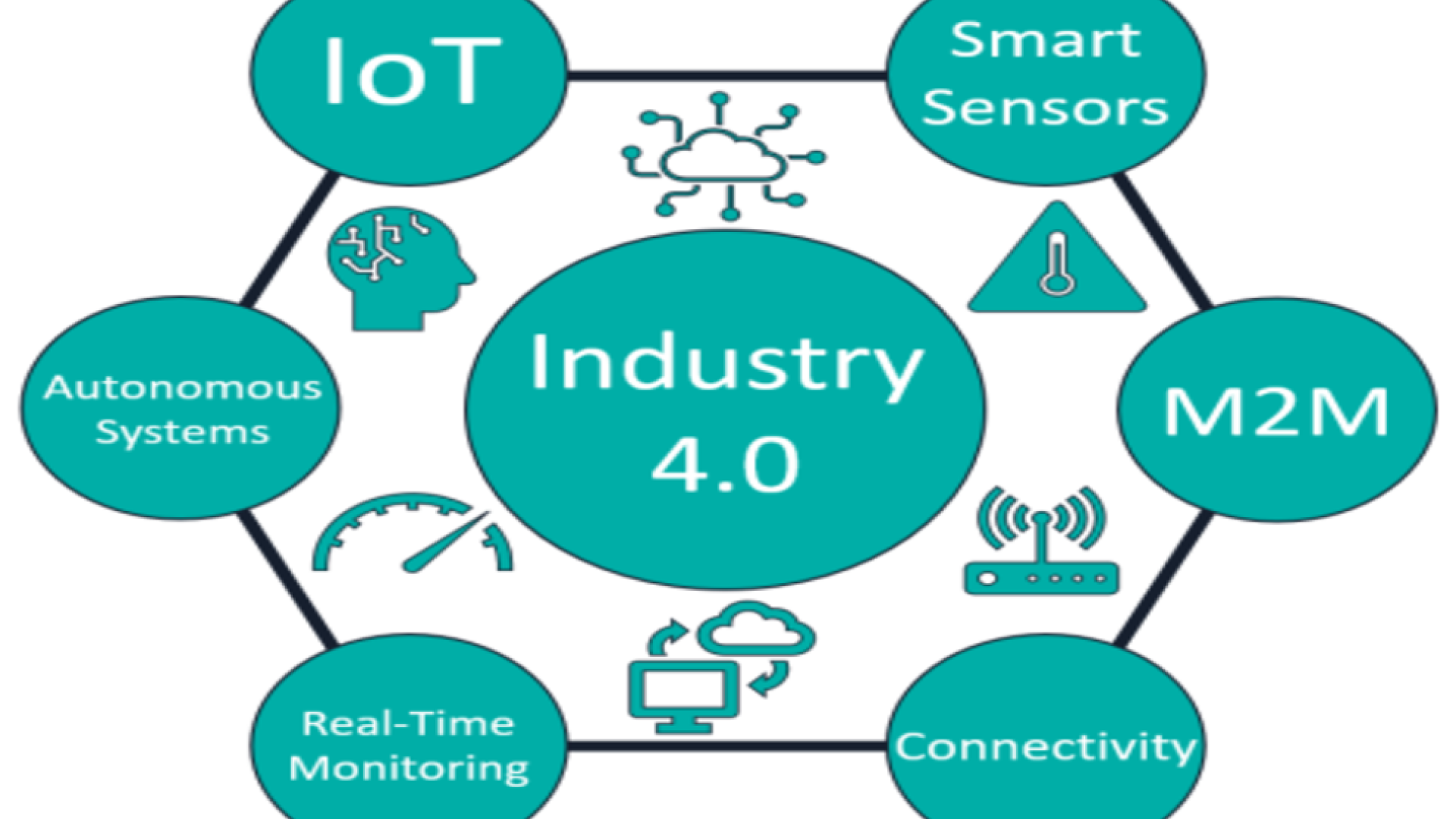

The implementation of Industry 4.0 has a far-reaching impact on industrial value creation. Studies on its opportunities and challenges for companies are still scarce. However, the high practical and theoretical relevance of digital and connected manufacturing technologies implies that it is essential to understand the underlying dynamics of their implementation. Thus, this study examines the.. The core concept of Industry 4.0 is to integrate advanced information technologies, especially emerging technologies, such as the Internet of Things, 5G & 6G, data analytics and management, artificial intelligence, cloud computing, and blockchain, to achieve a consistent transformation and upgrade of manufacturing and to reshape the value chain of industry and society. More research focuses on.