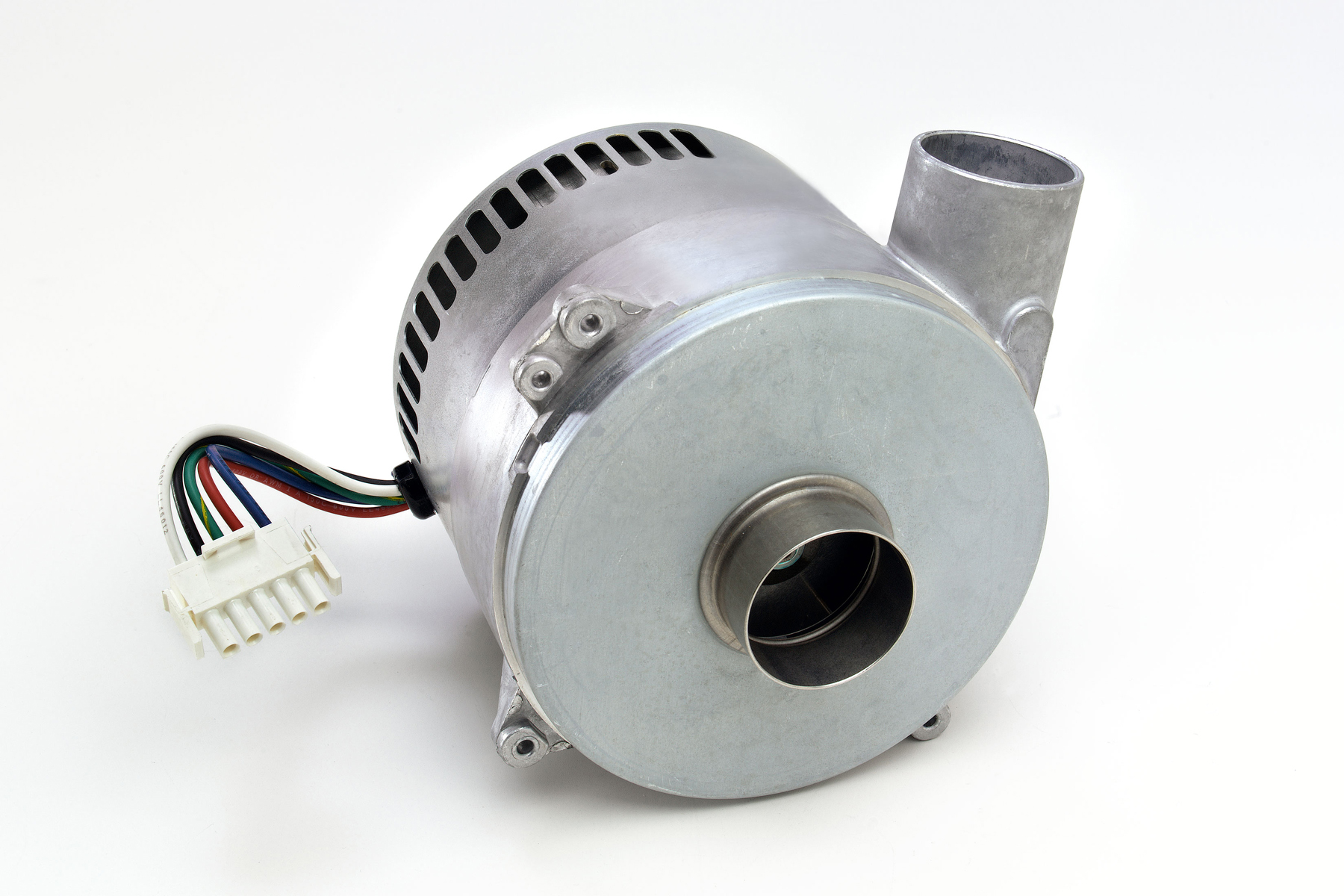

Semiconductor Industry blower motor Case Study: Blower motor systems utilize permanent magnet – PM – motor technology. The high-speed permanent magnet motors helped increase the speed of the fan, thereby providing better mixing of chamber gas.. Industrial blower fans are different from axial fans due to the way they move air. Centrifugal blowers are like industrial blowers because they have one of seven types of wheels or blades that take in air through the inlet of the blower housing section. This is different from an axial or industrial axial because they use a propeller to bring.

FASCO Direct Drive Blower Motor, 1/30 HP, Shaded Pole, Nameplate RPM

HVAC Blower Motor Blower Motor W/ Wheel

MARATHON MOTORS Direct Drive Blower Motor 2 Speed, Open AirOver, Stud

DC motor with blower

GENTEQ Direct Drive Blower Motor Goodman OEM Repl, 1/2 HP, 1,130

1 HP, 120 VOLT, 6.8 AMP BLOWER MOTOR The Spa Works

Single Phase 1 To 10 HP Heavy Duty Industrial Blower at Rs 18000 in

DAYTON, 1 Speed, Open AirOver, Direct Drive Blower Motor 4HZ64

35352 New Universal 12 Volt Blower Motor CCW rotation vented with wheel

All Points 681114 Burner Blower Motor 115V, 3100 RPM

Brushless DC Blowers

Star Balancing Mild Steel, Cast Iron Centrifugal Industrial Air Blower

CARRIER BRYANT Blower Assembly with Variable Speed Blower Motor ECM 3.0

CENTURY, 3 Speed, Open AirOver, Direct Drive Blower Motor 4MB30

MARATHON MOTORS Direct Drive Blower Motor, 1/3 HP, 3Phase, Nameplate

ACDelco 1580664 HVAC Blower Motor

GENTEQ, Trane OEM Repl, 1/2 HP, Direct Drive Blower Motor 6DLP53S014

ASC & ASP RangeSide Channel Blowers SPECK ABC SPECK ABC UK LTD

Direct Drive Blower Motor, 1/2 HP, 115 Volt, 1625 RPM Packard Online

D365 Fasco 1/25HP Fan & Blower Electric Motor, 1500RPM

These centrifugal blowers are ideal for electronic cabinet cooling, clean room modules, heat exchangers, air filtration, military HRAC, air showers, plastic extrusion, fume hoods, pharmaceutical equipment and semiconductor industry. TFD Blowers feature TEK backward curved airfoil impellers, the industry’s quietest and most efficient OEM.. SiC MOSFETs simplify inverter integration in motors [5] As a result, a drive solution using CoolSiCTM MOSFET technology can achieve as much as 50% reduction in losses (assuming similar dv/dt), based on lower recovery, turn-on, turn-off, and on-state losses. The CoolSiCTM MOSFET also has lower conduction losses than an IGBT especially under.